eSN is closed for eSN2026#JP-CN mission to Japan/China March 2026 - Order fulfilment resumes 16th March | Now Club | Group Ride Guide | Workshops: BSG / On The Run

Motor Hall Sensor 41F on 60 degree PCB (NAMI Burn-e etc)

SKU HALL-41F/3on60

AU$16.36

Bulk pricing available for quantities of 2 units or more

Motor positioning instrument for hall motors (sinewave controllers).

In stock: 8 available

1

Buy more, save more

| Quantity | Price per item | Discount |

| 2 items | AU$14.55 | 11% off |

| 5 items | AU$12.73 | 22% off |

Save this product for later

Customer reviews

Reviews only from verified customers

No reviews yet. You can buy this product and be the first to leave a review.

Motor Hall Sensor 41F on 60 degree PCB (NAMI Burn-e etc)

Product Details

Brand: by eScootNow

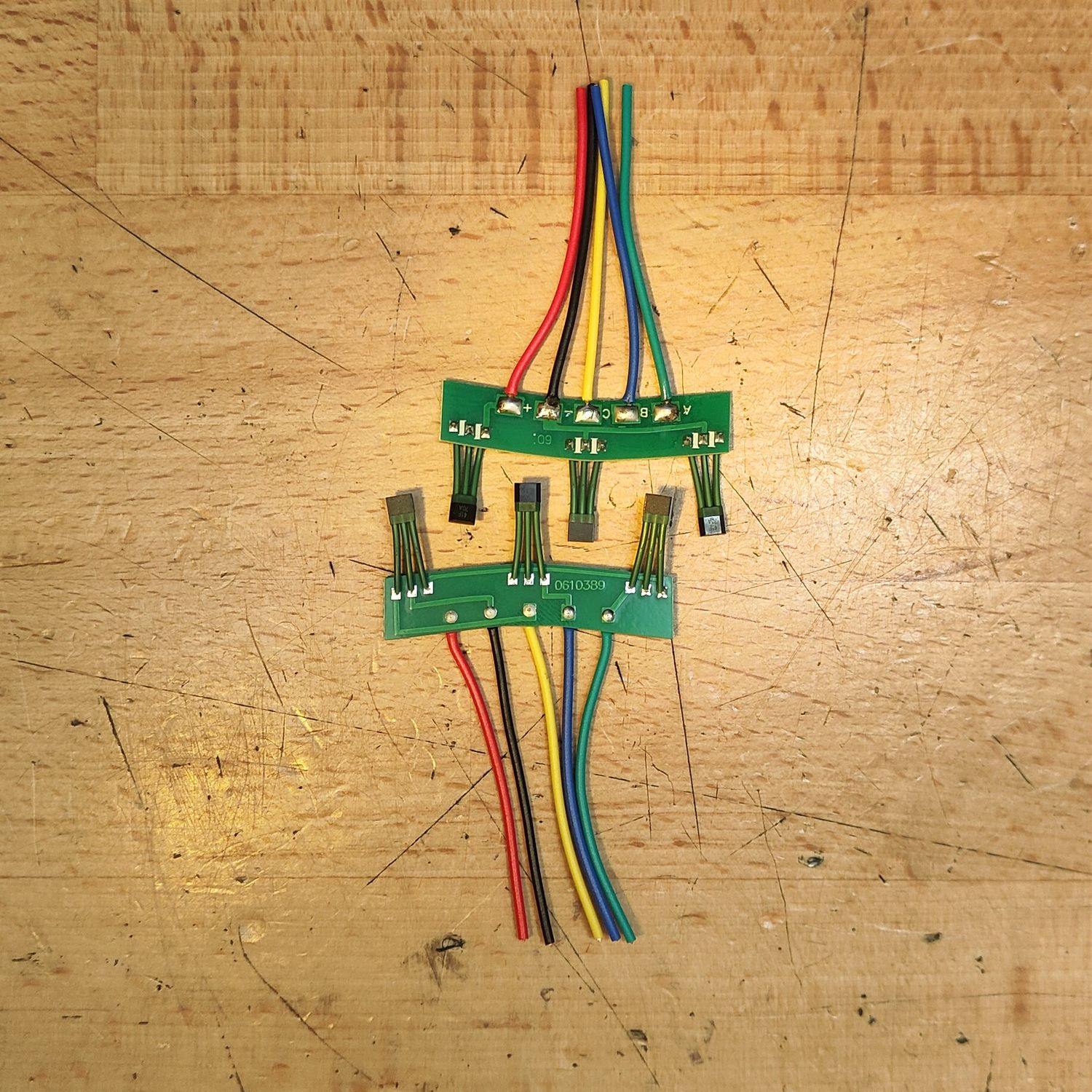

- 41F hall sensors are a common sensor used on eScooter motors, such as NAMI Burn-e 1500w motors.

- Hall sensors are responsible for wheel positioning (rotation / speed). They typically have 5 relatively thin wires that ultimately lead to the controller. If there is a fault with hall signalling, errors are thrown (such as 201 rear / 202 front motor error on NAMI systems) or throttle may cut out unexpectedly. Often they can be intermittent and get worse as the sensors degrade. It is not recommended to "ride through" errors, as the positioning plays an important roll high current switching (and stress on controller).

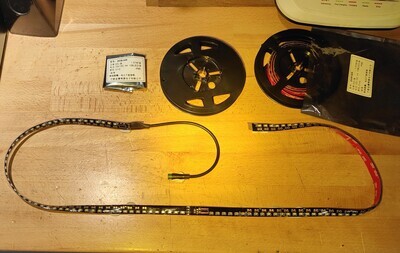

- Supplied as three 41F sensors (which are the most commonly used amongst eScooters) factory fitted on PCB with the 5 flylead wires (as shown). Order quantity two (2) for both front and rear wheels.

- Often sensors are cut from the PCB and retrofitted to existing hall sensor PCB and/or cut to modify the length for appropriate placement. PCB's are not universal / common amongst motors, each motor typically has it's own custom-shaped board. eSN supplies the complete board (PCB) as reference.

Notes:

- The 41F is understood to be "drop in replacement" in NAMI Motors, however the reports do not indicate if the halls themselves are dropped in (retrofitted), or the entire PCB assembly is "drop in replacement". eSN understands the former is the case, feedback is welcome.

- You typically clean out the motor (rust etc), assess bearings and fit new seals (e.g. NAMI) when renewing halls.

- Video demonstrates testing https://m.youtube.com/watch?v=vZUXqfdzQb0

You May Also Like

![TurboTouch FZ Coil & Oil Adjustable Shock Absorbers [Fangzhong | KKE (NAMI OEM)] TurboTouch FZ Coil & Oil Adjustable Shock Absorbers [Fangzhong | KKE (NAMI OEM)]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/5038246652.jpg)

TurboTouch FZ Coil & Oil Adjustable Shock Absorbers [Fangzhong | KKE (NAMI OEM)]

TurboTouch FZ Coil & Oil Adjustable Shock Absorbers [Fangzhong | KKE (NAMI OEM)]

Factory fabricated to eSN's specification across 18 variants in length, spring force & assemble. Suits NAMI Burn-e & Klima, Kaabo Wolf GTR & Mantis GT, Teverun Fighter, KuKirin G2 Master, VSETT & Zero etc

AU$158.18

NAMI NFC (suit Burn-e, Klima and Blast)

NAMI NFC (suit Burn-e, Klima and Blast)

Card reader module with cards

AU$104.55

TurboTap NFC Bypass Switch for NAMI

TurboTap NFC Bypass Switch for NAMI

Replaces or compliments NFC Card reader. Allows second headlight to be fitted.

AU$31.82

NAMI Throttle (suit Burn-e, Klima, Stellar and Blast)

NAMI Throttle (suit Burn-e, Klima, Stellar and Blast)

Horizontal, Wuxing 108X

AU$30.91

NAMI Horn Connector (cable suit Burn-e, Klima and Blast)

NAMI Horn Connector (cable suit Burn-e, Klima and Blast)

Connects horn to main cable.

AU$24.55

NAMI Horn (suit Burn-e, Klima and Blast)

NAMI Horn (suit Burn-e, Klima and Blast)

12V automotive, 480Hz.

AU$21.82

NAMI Light and Horn Switch (suit Burn-e, Klima, Stellar and Blast)

NAMI Light and Horn Switch (suit Burn-e, Klima, Stellar and Blast)

Switching instrumentation with turn, newer generation black 6-pin to show status LED

AU$34.55

NAMI Dashboard (TFT Display suit Burn-e, Klima and Blast)

NAMI Dashboard (TFT Display suit Burn-e, Klima and Blast)

With instrumentation switch, available in Non-NFC and NFC version

AU$168.18

NAMI Main Cable (main line / harness suit Burn-e, Klima and Blast)

NAMI Main Cable (main line / harness suit Burn-e, Klima and Blast)

Non-NFC & NFC / Front Turn Type

AU$95.45

NAMI Cable Holder (clamp suit Burn-e, Klima, Stellar and Blast)

NAMI Cable Holder (clamp suit Burn-e, Klima, Stellar and Blast)

Secures V3 main line and 2024 Q4 NFC

AU$14.55

NAMI Tail Light (suit Burn-e, Klima and Blast)

NAMI Tail Light (suit Burn-e, Klima and Blast)

Brighter rear turn signal indicators

AU$44.55

NAMI Extended Plastic Fender (mudguard suit Burn-e, Klima and Blast)

NAMI Extended Plastic Fender (mudguard suit Burn-e, Klima and Blast)

Replacement non-tail light extended fender

AU$22.73

NAMI Plastic Fender (mudguard suit Burn-e)

NAMI Plastic Fender (mudguard suit Burn-e)

With tail light cable routing

AU$29.09

NAMI Burn-e Charger 84.0V for 72V RGX16-2M 5A

NAMI Burn-e Charger 84.0V for 72V RGX16-2M 5A

[Alrightpower AP-PF3600CH08400050]

AU$226.36

NAMI Auto Closing Port Cover for Charging Port (suit Burn-e, Klima, Stellar and Blast)

NAMI Auto Closing Port Cover for Charging Port (suit Burn-e, Klima, Stellar and Blast)

Cap that protects charging port (protector)

AU$18.18

NAMI Charging Port

NAMI Charging Port

Panel socket for charging, suits Burn-e, Blast and Klima.

AU$17.73

NAMI Motor Cable Protection Plate (suit Burn-e, Klima and Stellar)

NAMI Motor Cable Protection Plate (suit Burn-e, Klima and Stellar)

Secures and retains motor wire

AU$12.73

NAMI Steering Damper (suit Burn-e)

NAMI Steering Damper (suit Burn-e)

Improves stability and ride handling

AU$204.55

NAMI Burn-e Max Controller 4000-A / 4000-B

NAMI Burn-e Max Controller 4000-A / 4000-B

72V, 50A, suits Max & 2/"3" Max

AU$209.09

NAMI Burn-e 2 Non-Max Controller 2400-A / 2400-B

NAMI Burn-e 2 Non-Max Controller 2400-A / 2400-B

72V, 30A, suits non-Max models of 2/"3"

AU$150.00

NAMI Motor 72V 1500w & 1000w (suit Burn-e)

NAMI Motor 72V 1500w & 1000w (suit Burn-e)

Replacement hub motor, as older bullet or newer waterproof (integrated) connector.

AU$359.09

NAMI Motor 60V 1000w (suit Klima)

NAMI Motor 60V 1000w (suit Klima)

Fitted with integrated connector

AU$313.64

NAMI Motor Seal Set (suit Burn-e, Blast, Klima & Stellar)

NAMI Motor Seal Set (suit Burn-e, Blast, Klima & Stellar)

Rotary shaft seal prevents moisture ingress to motor

AU$21.82

Rectangular "Logan" 4-Piston Brake Pad (Shimano D02S/D03S)

Rectangular "Logan" 4-Piston Brake Pad (Shimano D02S/D03S)

Suits Logan 4-Piston Callipers on NAMI Burn-e 2 Max, Zoom HB-890 & X4 on VSETT 10+ Apex & TurboBrake HB427-4S (& alt for HB427-4M "ears")

AU$10.91

Shimano B01S/M315 Brake Pad

Shimano B01S/M315 Brake Pad

Suits Logan 2-piston on NAMI Klima, Stellar Pro and late Burn-e 2 non-Max, NAMI Stellar & XOD H800/880 on early Dragon Cyclone Pro.

AU$10.45

NUTT Brake Pad (Cooling Enhanced)

NUTT Brake Pad (Cooling Enhanced)

Suits NUTT A5-D 2-piston calliper on early NAMI Burn-e, MUKUTA 10+, Limited models of Zero 10X/11X, Dragon Hunter X11, early Dragon Cyclone Pro & early VSETT and 4-piston callipers NUTT Y-5 & TurboBrake HB427-4M.

AU$16.36

![160mm Brake Disc Rotor Wave [TurboBrake | NAMI] 160mm Brake Disc Rotor Wave [TurboBrake | NAMI]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/4822181421.jpg)

160mm Brake Disc Rotor Wave [TurboBrake | NAMI]

160mm Brake Disc Rotor Wave [TurboBrake | NAMI]

Suits NAMI Burn-e & Blast, Dragon Hurricane, Predator & Cyclone and Teverun Fighter.

AU$18.18

![TR438 Valve Stem (Schrader suit Burn-e, Klima, Stellar and Blast) 12.5mm seat [NAMI/Aftermarket] TR438 Valve Stem (Schrader suit Burn-e, Klima, Stellar and Blast) 12.5mm seat [NAMI/Aftermarket]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/5038236123.jpg)

TR438 Valve Stem (Schrader suit Burn-e, Klima, Stellar and Blast) 12.5mm seat [NAMI/Aftermarket]

TR438 Valve Stem (Schrader suit Burn-e, Klima, Stellar and Blast) 12.5mm seat [NAMI/Aftermarket]

Uniquely provisioned on NAMI makes (all models including Burn-e, Klima, Stellar & Blast).

AU$10.91

Late Feb

![CST 90/65-6.5 Road Tyre (tubeless) [C-9316] CST 90/65-6.5 Road Tyre (tubeless) [C-9316]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/5038236135.jpg)

CST 90/65-6.5 Road Tyre (tubeless) [C-9316]

CST 90/65-6.5 Road Tyre (tubeless) [C-9316]

81mm at bead, 50PSI, suits 6.5" rims of NAMI Burn-e, Wolf Warrior 11>, Dragon Hurricane, Predator 6.5" rear, Zero 11X & VSETT 11+.

AU$43.64

![TurboTrack GPS Tracker [Eelink TurboTap] TurboTrack GPS Tracker [Eelink TurboTap]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/products/356543067/5516976431.jpg)

TurboTrack GPS Tracker [Eelink TurboTap]

TurboTrack GPS Tracker [Eelink TurboTap]

Immobilise, Track & Recover with plug-and-play GPS trackers for select models of NAMI, Kaabo, Teverun, Zero & Dragon eScooters.

AU$218.18

![NAMI Electric Brake Switch Sensor (Hall & Mechanical) M8 (suit Burn-e, Klima and Blast) [Logan] NAMI Electric Brake Switch Sensor (Hall & Mechanical) M8 (suit Burn-e, Klima and Blast) [Logan]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/4936646021.jpg)

NAMI Electric Brake Switch Sensor (Hall & Mechanical) M8 (suit Burn-e, Klima and Blast) [Logan]

NAMI Electric Brake Switch Sensor (Hall & Mechanical) M8 (suit Burn-e, Klima and Blast) [Logan]

Hall sensor (suit older NAMI models) and mechanical (suit newer NAMI models). May suit NUTT/XOD.

AU$18.18

![Electric Brake Switch Sensor (Hall) M8 & M6 [TurboBrake/Dragon | Zoom/Kaabo] Electric Brake Switch Sensor (Hall) M8 & M6 [TurboBrake/Dragon | Zoom/Kaabo]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/3555453972.jpg)

Electric Brake Switch Sensor (Hall) M8 & M6 [TurboBrake/Dragon | Zoom/Kaabo]

Electric Brake Switch Sensor (Hall) M8 & M6 [TurboBrake/Dragon | Zoom/Kaabo]

Hall Sensor suits TurboBrake and Zoom levers including Dragon/Langfeite models of Predator, Hurricane, Slayer, late Cyclone, Lightning V2 & The Beast, Teverun Fighter series, models of Kaabo Wolf, Mantis Pro and select VSETT / Zero.

AU$15.00

Display prices in:AUD

![Throttle conversion cable for Kaabo/NAMI to Wuxing KTRB throttle [TurboTap | TurboThrottle] Throttle conversion cable for Kaabo/NAMI to Wuxing KTRB throttle [TurboTap | TurboThrottle]](https://d2j6dbq0eux0bg.cloudfront.net/images/60508924/5038231981.jpg)